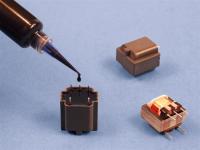

Versatile Master Bond two component, room temperature curing epoxy and urethane modified epoxy systems offer exceptional protection against wear. These products withstand exposure to abrasive slurries/solids, chemical attack, cavitation, impact and elevated temperatures. Specific formulations feature toughness, dimensional stability, superior compressive strength and high gloss/low friction. Correctly prepared surfaces are conveniently rebuilt to meet the challenges of harsh environments including fine/coarse particles, abrasion, turbulence, erosion/corrosion.

Typical Applications for Master Bond Wear Resistant Coatings

These compounds are designed to extend the life of equipment and reduce the need for spare parts. Products are commonly employed on:

- Pumps

- Hoppers

- Valves

- Centrifuges

- Wear plates

- Chutes

- Impellers

- Pipe Bends

- Fan Blades

- Condensers

Master Bond wear resistant coating systems are easy to mix and are solvent free. They can be applied by brush or trowel on complex shapes even on vertical surfaces without sagging or dripping. Shrinkage upon cure is negligible. Adhesion to rubbers, ceramics, composites, most plastics and metals including steel, stainless steel, cast iron is outstanding.

Fast setting formulations have been developed for emergencies. They allow rebuilt worn or damaged parts to be quickly placed in services eliminating costly downtime. Formulations have been tailored to meet specific requirements and are used in power plants, chemical processing facilities, mines, pulp/paper manufacturing, business equipment and in industrial automation.

Most Popular Wear Resistant Coatings

|

EP21SC-1 High performance, abrasion resistant epoxy system. Silicon carbide filled compound. Convenient one to one mix ratio. Resists thermal cycling and many chemicals. Exceptional bond strength. Low coefficient of thermal expansion. Excellent electrical insulation properties. Paste consistency. Serviceable from -60°F to 250°F. |

|

EP30D-7 Urethane-modified epoxy system. Superior toughness and abrasion resistance. Cures at room temperatures. Compound flows easily and smoothly. Versatile cure schedule. |

|

EP30D-10 Optically clear, elastomeric system. Urethane modified epoxy. 100% reactive. Serviceable from -100°F to 220°F. Long working life. Resistant to thermal cycling. High impact strength. Outstanding flexibility. Protects against abrasion. Minimal linear shrinkage upon cure. Low moisture permeability. |

|

Supreme 45HTQ Two component, toughened, quartz filled epoxy with exceptional abrasion resistance. Heat curing system. Long working life after mixing. High compressive strength. Superb dimensional stability. Serviceable from -60°F to +450°F. Withstands exposure to petrochemicals acids, bases, solvents. Good strength retention at elevated temperatures. Successfully tested for 1,000 at 85°C/85% RH. |