Bonding, sealing, potting/encapsulation compounds provide protection against cracking, delamination, leaking, deformation, mechanical failure from rapid extreme temperature fluctuations. These epoxy, silicone products are designed to ensure that parts, components, devices will perform as necessary upon exposure to severe conditions. Examples include:

- Internal combustion engines

- Fluid handling devices

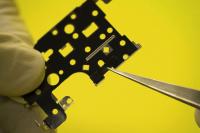

- High density electronic packaging

- Launch vehicles

- Aircraft components

- LEDs

- Sensors

- Transformers

They are formulated to feature high Tg and flexibility to absorb thermally induced stresses. Selecting the proper grade requires careful consideration of:

- Exact temperature gradients

- Frequency of cycles

- Length of time at each gradient

Thermal shock resistant potting/encapsulation compounds exhibit low viscosity, toughness, long working life and low exothermic properties. They offer high voltage insulation and guard delicate assemblies, heat generating devices and stress sensitive components. Heat dissipative systems are also available for use.

High strength one and two component adhesives systems have exceptional peel/shear strength and adhere well to dissimilar substrates with different coefficients of thermal expansion and contraction.

Most Popular Products

|

Supreme 10HT One part structural epoxy with high bond strength and excellent adhesion to similar and dissimilar substrates, especially composite materials. Requires oven curing at 250-300°F. NASA low outgassing approved. Serviceable from 4k to +400°F. Tough and durable. 85°C/85% RH resistance. |

|

EP21TDC Superior toughness. Ideal for bonding similar and dissimilar substrates. Withstands aggressive thermal cycling. Convenient one to one mix ratio. Good flow properties. User friendly. Versatile cure schedule. Serviceable from -60°F to +250°F. |

|

MasterSil 151AO Thermally conductive silicone casting, potting and sealing system. Thermal conductivity of 0.35-.0.54 W/(m•K). Electrically isolating. Low viscosity system bonds well to a wide variety of substrates. Remarkable flexibility. Temperature resistant from -65°F to +400°F. White color. |

|

EP110F8-3 High performance two component epoxy system for potting, sealing, encapsulating and casting. Low viscosity liquid with good flowability. Exceptional thermal shock resistance. Superb mechanical and electrical insulation properties. Serviceable from -100°F to +300°F. |

|

MasterSil 705TC Thermally conductive and electrically isolating. Easy to use silicone for high performance bonding, sealing and coating. Non-corrosive and room temperature curable. Ideally suited for applications requiring flexibility and high temperature resistance. |

|

EP36AO Thermally conductive, electrically insulative B-stage toughened epoxy. One part system. Ideal for potting and encapsulation. Capable of withstanding rigorous thermal shocks. Serviceable from -100°F to +500°F. Available in 30 gram cookies. Meets NASA low outgassing specifications. |

|

MasterSil 323 Two part silicone paste for bonding, sealing and encapsulating applications. Optically clear in thin sections. Outstanding flexibility. Contains no solvents or diluents. Low to moderate viscosity. Low dielectric constant. Addition cured, no by-products released during cure. Serviceable from -65°F to +400°F. |

|

EP37-3FLFAN Highly flexible, thermally conductive/electrically insulative epoxy system. Low viscosity. Cures readily at room temperature. Long working life. One to one mix ratio by weight or volume. Serviceable from 4K to +250°F. Good physical strength and chemical resistance. |