The Benefits of Silver Filled Adhesives

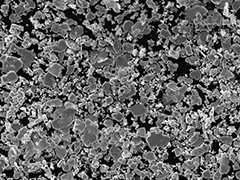

In the realm of electrically conductive epoxies and silicone, there is nothing like silver. Not only does silver have very high electrical conductivity, it also retains its low resistance over many years, even decades. This is much more desirable than other metals that are highly conductive, such as copper, which lose their conductivity when oxidized. Not so for silver because silver oxide, unlike copper oxide, is highly conductive. Nickel is sometimes used as a conductive filler because of cost issues but realistically, it is best suited for shielding applications. And nickel will oxidize as well. Graphite is sometimes needed as a conductor because of magnetic considerations. But it isn’t nearly as conductive as silver although it retains its limited conductivity rather well. Finally, there is gold. On the positive side, it is highly conductive and doesn’t oxidize, but the cost makes it almost prohibitive. With conductive epoxies and silicones, there is nothing like silver.

One and two component, silver filled, electrically conductive compounds feature low volume resistivity and high reliability. They offer excellent physical strength properties, superior substrate adhesion and uniform electrical conductivity. They are often used as replacements for solder.

Advanced Properties of Master Bond Silver Filled Adhesive Systems

Master Bond silver filled adhesives are designed to meet specific performance requirements. Certain grades offer:

Master Bond silver filled adhesives are designed to meet specific performance requirements. Certain grades offer:

- Serviceability at high and low temperatures

- Low stress

- High shear and peel strength

- Resistance to thermal cycling

- Low outgassing

- USP Class VI approval

Applications of Silver Filled, Electrically Conductive Systems

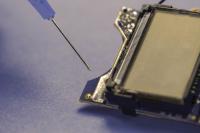

These products are commonly employed in the automotive, medical, appliance, electronic, electrical, microwave, aerospace and electro-optic industries. Specific applications include:

- Die attach

- SMD attach

- EMI/RFI shielding

- Grounding

- Solder replacement

- Flip chip attachments

- PCB repair

Most Popular Electrically Conductive, Silver Filled Polymer Systems

|

EP77M-F Rapid room temperature curing silver filled electrically conductive adhesive. One to one mix ratio by weight or volume. Fixture time within 5-7 minutes even in small volumes. Exceptional low volume resistivity. Low outgassing. Superior bond strength to similar/dissimilar substrates/ Serviceable from -60°F to +250°F. |

|

EP21TDCSFL SIlver filled electrically conductive epoxy adhesive. Low volume resistivity. Highly flexible. Excellent peel and shear strength. Low linear shrinkage upon cure. Good flow properties. Cures at room temperature. Resists vibration, impact, thermal cycling. Serviceable from 4K to +250°F. |

|

EP3HTS-LO High performance, one component silver filled electrically conductive adhesive. Low volume resistivity. Bonds wells to a wide range of substrates. Meets NASA low outgassing requirements. Thermally conductive. Rapid cures at moderate temperatures. Easy to dispense. Serviceable from -60°F to +400°F. |

|

FL901S High performance, silver filled epoxy adhesive film system with outstanding electrical and thermal conductivity. Superior mechanical strength, convenient handling, good storage stability and fast cures at moderate temperatures. Specialty preforms are available. Serviceable from -100°F to +500°F. |

|

EP21TDCS Two component, silver filled electrically conductive epoxy system with a convenient one to one mix ratio and very low volume resistivity. Cures at room temperature. Superior toughness. Serviceable from 4K to +275°F. Withstands rigorous thermal cycling. Successfully tested for 1,000 hours 85°C/85% RH. Exhibits superb thermal conductivity. |

|

MasterSil 705S Silver filled, one-part, no-mix, non-corrosive silicone system. Shore A hardness 70. Cures at room temperatures when exposed to atmospheric moisture. Extremely low volume resistivity. Most effective when applied in thin sections. |

|

EP77M-FMed Rapid room temperature curing silver filled electrically conductive adhesive. One to one mix ratio by weight or volume. Fixture time within 5-7 minutes even in small volumes. Exceptional low volume resistivity. Low outgassing. Superior bond strength to similar/dissimilar substrates. Serviceable from -60°F to +250°F. |

|

Supreme 3HTS-80 One component, silver conductive epoxy adhesive featuring high shear and high peel strengths. Cures at 175°F to 185°F. Bonds well to many substrates. Single part no mix system. Serviceable from -100°F to +350°F. Requires refrigeration, no freezing necessary |