Performance Properties of Master Bond Adhesive Films and Preforms

Grades of our epoxy films and performs can be adjusted to meet specific requirements of:

- Flexibility

- Electrical/thermal properties

- Temperature & chemical resistance

Successful industry applications include:

- Substrate attachment with minimal squeeze out

- Heat sink bonding

- Lid sealing

- Stress absorption

- Hybrids

- Connectors and other electronic assemblies

- EMI/RFI Shielding

- Structural bonding

- Static dissipation

How Do You Use an Epoxy Film Adhesive?

Learn how to properly apply epoxy film adhesive system FLM36 in this video presentation.

Benefits of Film and Preform Adhesives

- Ready to use

- Remains in one place after application

- Bondline uniformity

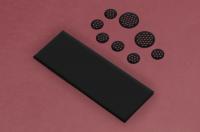

- Preforms can be supplied in intricate shapes

- Can narrow bondline widths

- Suitable for high volume production

Popular Master Bond Film & Preform Adhesive Systems

|

FLM36 B-staged film adhesive/sealant. Outstanding thermal cycling capabilities and structural properties. Offers superior toughness and flexibility. Excellent strength retention at elevated temperatures. Thermally conductive/electrically insulative. Provides uniform bond line thickness. Serviceable from -100°F to +500°F. Preforms are available. |

|

FL901S High performance, silver filled epoxy adhesive film system with outstanding electrical and thermal conductivity. Superior mechanical strength, convenient handling, good storage stability and fast cures at moderate temperatures. Specialty preforms are available. Serviceable from -100°F to +500°F. |

|

FL901AO High performance, thermally conductive, electrically insulative, resin based epoxy adhesive film system. Offers superior mechanical strength, convenient handling, good storage stability and fast cures at moderate temperatures. Uniform bond line thickness. Special preforms can also be prepared in multiple shapes and sizes. Serviceable from -100°F to +400°F. |